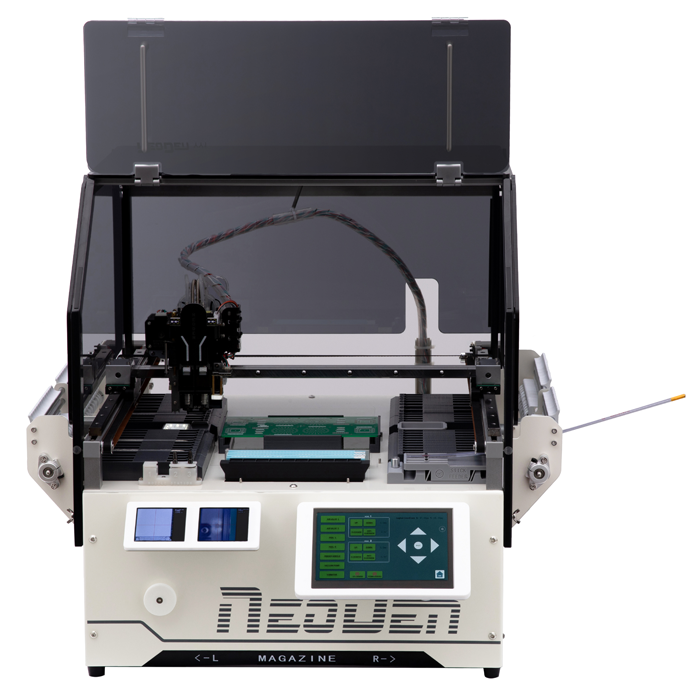

NeoDen YY1

NeoDen YY1 is a Low-Cost Desktop SMT Mounter with Two Nozzle and Three Auto nozzle changer Option, 103 Feeder Location, Dual camera Vision system, High Accuracy placement, Loose, Cut Tape component Pickup.

Machine is Having a very User-Friendly GUI with which reduces the Learning curve of the software, and the user can master it in few Hours. NeoDen YY1 is very well suited for R&D institutions, small scale Production Units, Hobbyists, who will be having various circuits to assemble with loose/cut tape /Strip components in hand. Considering the work ability factor on the machine it gives a very flexible nature of mounting the PCB for job, user can fix the PCB anywhere on the working bed, unlike similar machines which have dedicated Set Zero point.

NeoDen YY1 is a Powerful Mounting machine with the use of Latest Cortex MCU Engine and the very new technology Drive Systems, Pneumatics, Component reel movement, Image Capture and Recognition.