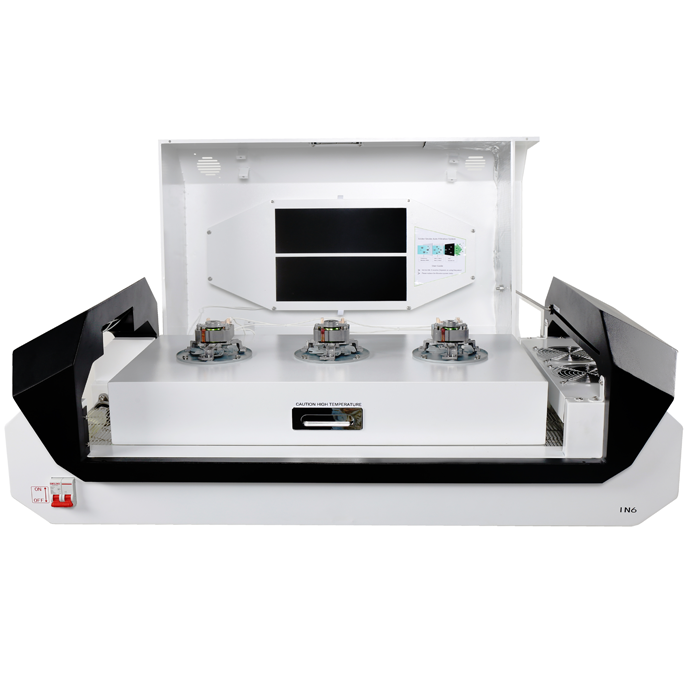

NeoDen IN6

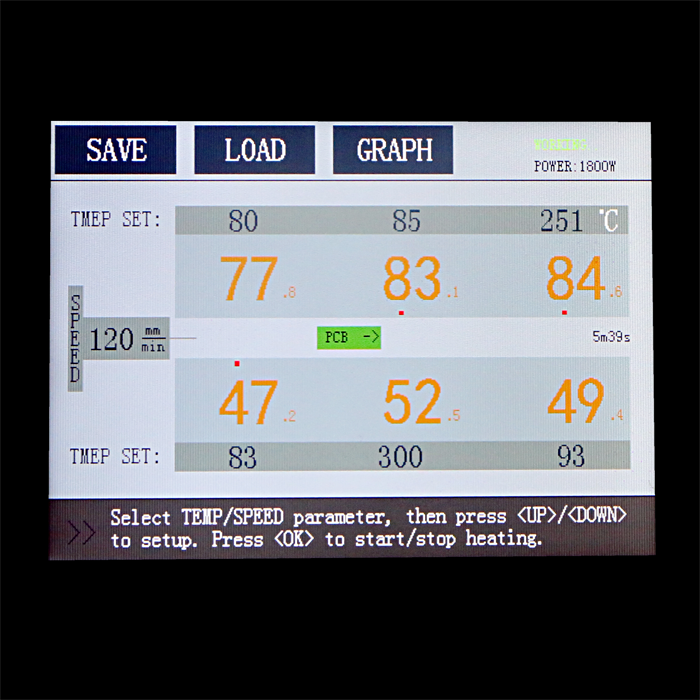

The NeoDen IN6 is a compact and efficient reflow oven designed to enhance the soldering process in electronic manufacturing. With its advanced features, including precise temperature control and a built-in smoke filtering system, it ensures consistent and high-quality results. Its user-friendly design and versatility make it an ideal choice for both prototyping and medium-scale production, offering reliability and convenience for modern manufacturing needs.