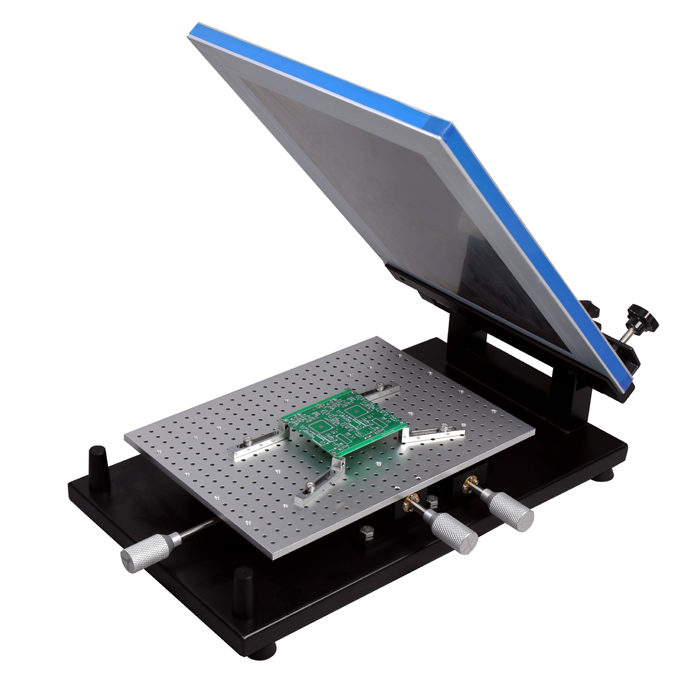

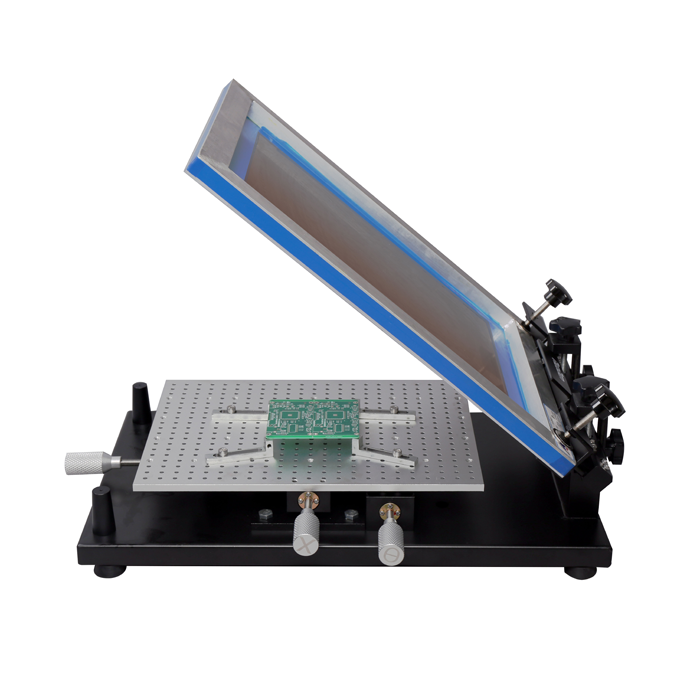

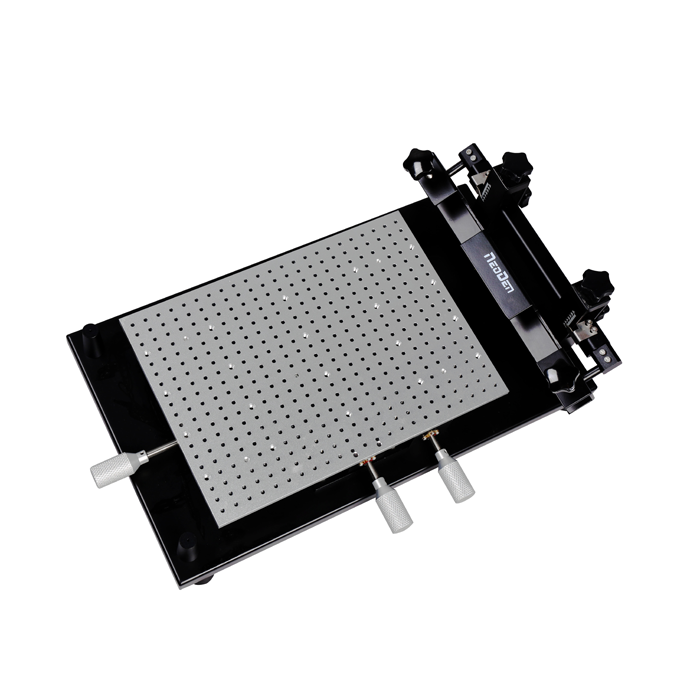

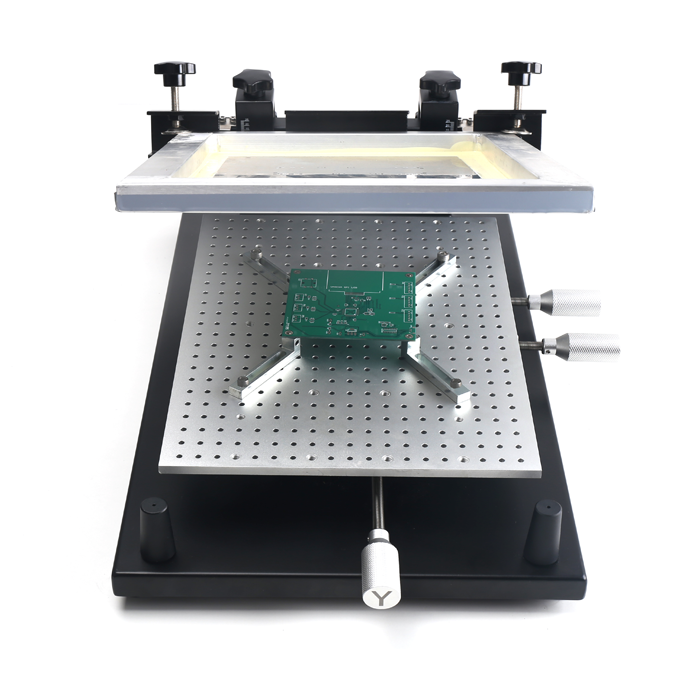

FP-2636 Framed

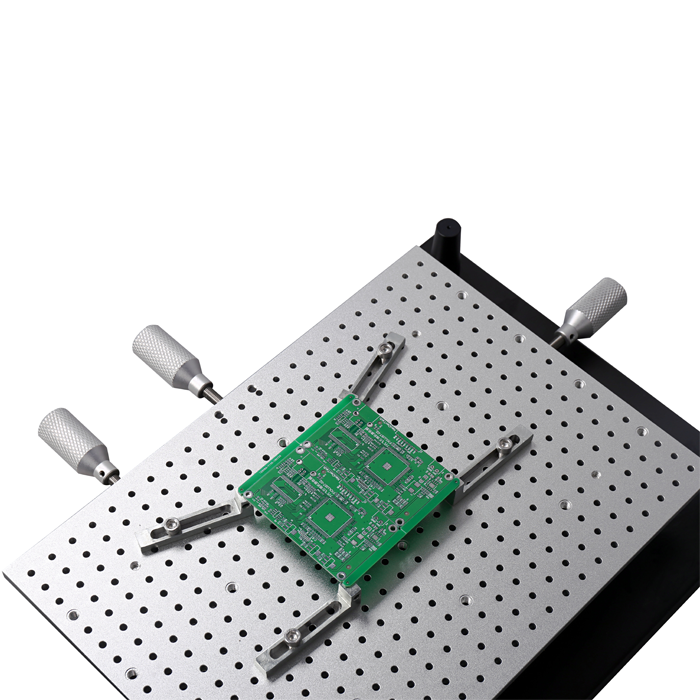

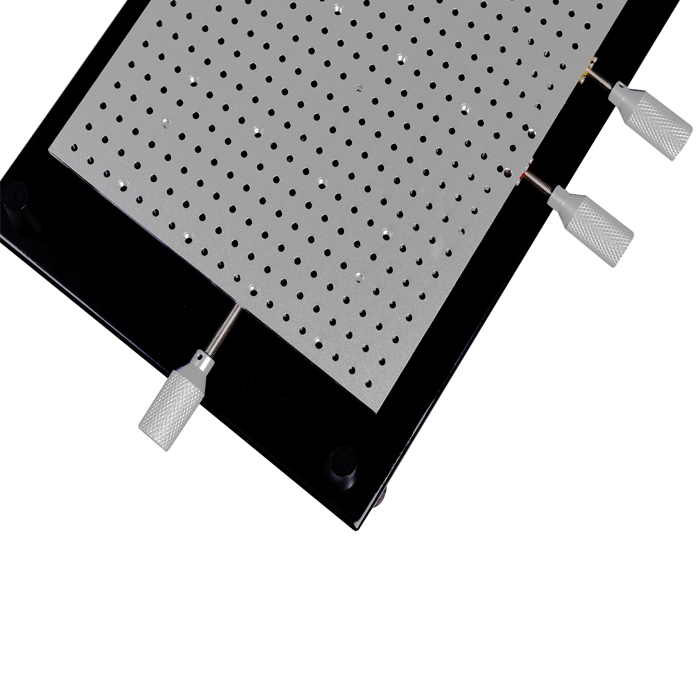

The FP2636 Manual Solder Printer for Framed Stencils is a simple way to apply solder to your PCBs every time. Proper solder application is frequently overlooked as a critical step in the SMD process. Without careful control of the placement and thickness of the solder paste, the results of reflow soldering can be amateur at best, to nonfunctional at worst. The operation of the printer is simple. First, clamp a framed stencil (available at very low cost from most PCB manufacturing houses) into the printer. Then, place the PCB on the included locator fixtures. Using the Vernier controls, move the PCB fixture until the solder pads perfectly align with the holes. Finally, move the solder over the stencil with the squeegee blade (included).