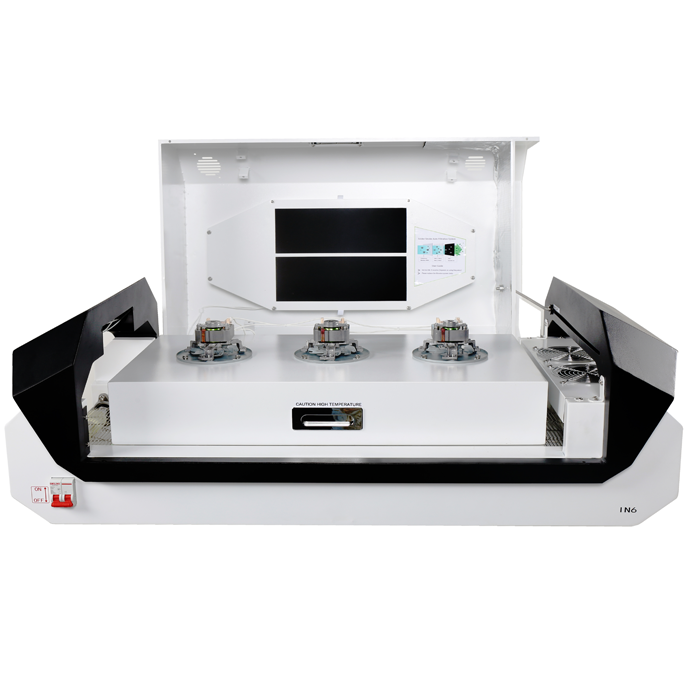

NeoDen IN6C

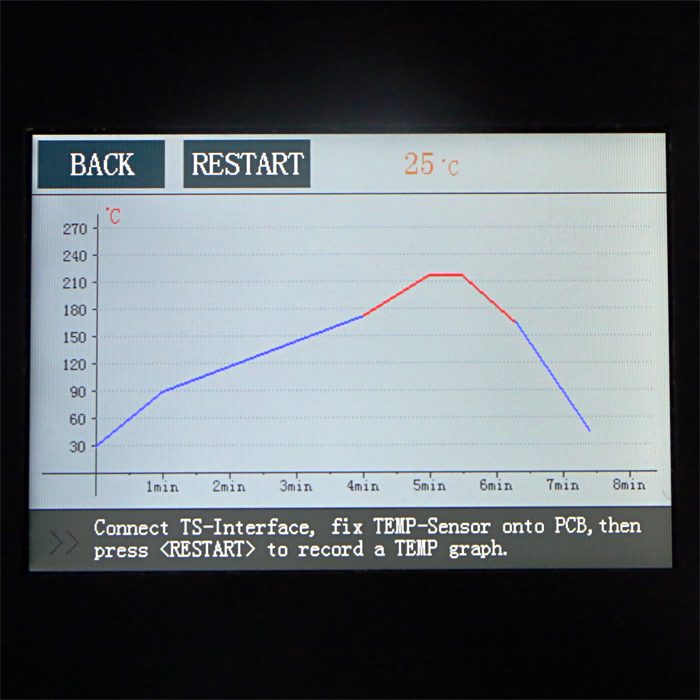

The IN6C, a newly designed and manufactured reflow oven by NeoDen Tech, boasts six temperature zones, a built-in welding smoke filtering system, working file memory function, and a heat-up reminder. These features contribute to its intelligence, innovation, and compact design.